Top Reliability Tips for Maintaining Food & Beverage Processing Pumps

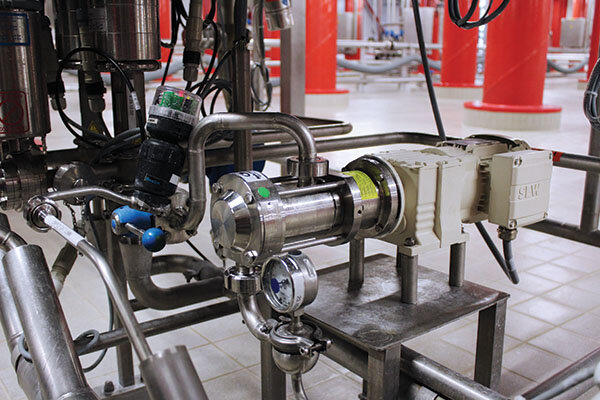

/Food and beverage pumps are subjected to extensive and harsh cleaning procedures to ensure that they meet all health regulations.

By Michelle Segrest, Navigate Content, Inc. — Reporting for Maintenance Technology Magazine

It can be as smooth and clear as water or wine, or as sticky and thick as cookie dough or peanut butter. Regardless the viscosity, one thing remains a top priority when pumping processed food and beverages—no corners can be cut when it comes to keeping the systems clean and hygienically safe.

“Keeping this equipment sanitary is no joke in our business,” said Mike Dillon, president of SEEPEX Inc., an Enon, OH, manufacturer of pumps that process milk and dairy products, wine and beer, fish, baking goods, sugar, fruit and vegetables, poultry and meat, and other food products. “I have seen manuals for one company that are more than 200 pages of procedures just for keeping the equipment clean. The guidelines are strict, and they should be. On every changeover, and also during production, we must ensure that this equipment is completely flushed of any bacteria or other residual material.”

Until the 1950s, closed systems were completely disassembled and cleaned manually after every shift and changeover. The advent of clean-in-place (CIP) procedures changed the industry. CIP is a method of cleaning the interior surfaces of pipes, vessels, process equipment, and associated fittings while the equipment remains online. Industries that rely heavily on CIP are those requiring high levels of hygiene, including dairy, beverage, brewing, processed foods, pharmaceutical, and cosmetics.

CIP is faster, less labor intensive, and more repeatable than COP (clean-out-of-place), which requires complete disassembly of the production line to clean it properly. CIP also poses less of a chemical-exposure risk to people. It started as a manual practice involving a balance tank, centrifugal pump, and connection to the system being cleaned. Since the 1950s, CIP has evolved to include fully automated systems with programmable logic controllers, multiple balance tanks, sensors, valves, heat exchangers, data acquisition, and specially designed spray-nozzle systems.

In addition to advanced CIP practices, this is an industry that is heavily and strictly monitored by many governing bodies, including, but not limited to:

Food and Drug Administration (FDA), Silver Spring, MD

European Hygienic Engineering & Design Group (EHEDG), Frankfurt, Germany

3-A Sanitary Standards, McLean, VA

United States Dairy Association (USDA), Washington

National Sanitation Federation (NSF), Ann Arbor, MI

County, state, and federal health inspectors

U.S. Environmental Protection Agency (EPA), Washington.

Most large food and beverage manufacturers must have representatives from one or more of these agencies on site any time their equipment is running to perform scheduled and random checks of the sanitary discrepancy of the equipment.

Cleaning of plant process equipment, pumps, valves, heat exchangers, tanks, vessels, mixers, and other equipment with the proper chemicals and methods is determined by the individual plant’s sanitary departments. Some systems still use the COP method, while some food pumps are designed for sterilization-in-place (SIP), which provides sterilization with superheated steam during the cyclic operation of the pump.

Common CIP Examples for Food & Beverage Pumps

Dillon explained that, before CIP was common practice, the procedure was much more complex.

“The way it used to be in dairy, for example, you would show up for your shift, run your process, and then you would tear down everything—all the piping, tri-clamp fittings, and the pumps,” Dillon said. “The shift that was leaving took all the parts and put them in these big cleaning troughs where they had to use bottle brushes to clean out the pipes. The next shift had to do all the cleaning and all the reassembly. Everything that was produced on the shift had a number on it to trace it to that shift. If, for some reason, salmonella, or something like that, showed up, they could eliminate or call back all the production on that shift.”

CIP processes are similar, but without the disassembly. “With CIP, they don’t tear down everything, but there is a series of chemical flushes,” Dillon explained. “They use high-speed, high-volume centrifugal pumps because you have to get up to seven feet per second in velocity on the cleaning chemicals for them to do their job. They also run at very high heat. They are going to run caustic soda at really high flow rates through the entire line, and they also run nitric acid through it to kill everything. They finally finish it off with hypochlorite solution to sterilize it,” he added.

This is typically performed at 180 degrees Fahrenheit for about 90 minutes, Dillon stated. “Some of these guys think hotter is better. Some procedures are so severe that if you had a dead mouse in the line it would be dissolved. It’s pretty rough. It is a very aggressive chemical at very high temperature, and it is designed to kill everything that is in that line.”

This means the pipes must also be able to handle the abrasiveness of the cleaning materials.

“You have to be so careful,” Dillon said. “You can’t run the equipment normally the way you run it during CIP. If you do, yogurt, for example, may come out looking like skim milk. You must change the operation parameters between CIP and regular operation.”

USDA and FDA inspectors may be on site to determine the cleanliness of the system after each CIP. “They don’t care how you clean it, but it must be cleaned to their standard,” Dillon said. “If you are in a dairy plant, you must clean the system at least three times a day. Other products, for example chocolate, have less-stringent regulations. It just depends on what you are pumping.”

Inspectors will take samples and record bacteria counts. “The food industry in this country is incredibly regulated,” Dillon said. “You may have five or six different regulators coming into your plant unannounced. So the procedures must be strictly written and followed.”

The USDA and FDA have set procedures for what will kill bacteria, Dillon said, and it is all based on temperature and time. “The sterilization procedure for CIP is 176 degrees Fahrenheit for 12 minutes. This ensures that anything such as salmonella is dead. Some guys will take it to 220 degrees because it’s in a pressured system, just to see what happens, but this is not a good idea. The problem is this extreme heat can hurt some of the other materials, like rubber, for example. Thinking hotter is better is a common problem. Dead is dead. Bacteria doesn’t need to be deader than dead.”

Once the equipment is flushed with the chemicals, it is then flushed with clear water, combined with some chlorine. The final step is the sanitation stage.

Common Maintenance Issues for Food & Beverage Pumps

Experts in the industry describe four specific maintenance issues that can create havoc with food-and-beverage processing pumps.

Preprogrammed controls can be hard on CIP equipment. “Sometimes outside vendors who don’t understand this type of equipment are the ones who design the systems,” Dillon said. “For example, sometimes dead bands on tank levels in filling machines are set so tight that the motors are starting and stopping more often than they should. The pumps should be operating at varying speeds and never stopping.”

When the motor stops, it can cause backward motor operation, which can damage the mechanical seals in positive-displacement pumps. “There is much to consider, so it’s important to look at the system and how it operates and consider what you are pumping,” Dillon said. “Yogurt is more viscous than corn syrup, which is more viscous than carbonated water. Make sure the entire system is formatted to meet the needs of your product and the equipment you are using.”

Improper pump and material selection. “When a pump is not sized correctly, it can run too fast and with too much volume. This increases the wear and the cost of time and maintenance,” said Grant Gramlich, business development manager, Hygienic Americas for Dover Pump Solutions Group (PSG), Oakbrook Terrace, IL. “Improper system and piping designs on the pump inlet will cause cavitation, internal pump damage, premature wear, and failure.”

Dillon agrees this is a major issue. “One size does not fit all,” he stated. “What works well on a soft-drink-packaging line is not going to work well on a yogurt-packaging line. A standard CIP program for cleaning a positive-filtration pump will not necessarily work well for a lobe pump. Lobes need to be cleaned by hand. For progressive cavity pumps, you can only run the pump part of the time during CIP or it will shorten the life of the pump.”

Pumps running dry. “When a pump runs dry it can create wear on the seals, due to no lubrication between the seal faces,” Gramlich said. “This leads to excess heat and premature failure of the seals, which leads to downtime, and ultimately the loss of product, production, and profits.”

Dillon agrees that no pump should ever run dry. “You need to ensure that fluid is in the line,” he stated. “A positive-displacement pump will continue to build pressure until something breaks. Pressure generates torque on the pipe and wear and tear on bearings and mechanical seals. You will pay for it in increased electric costs and maintenance.

Pump seal leaks. “In addition to affecting production, a leaking seal can create a safety hazard,” Gramlich said. “Seal leaks are also a path for contaminants to enter the pump, either by airborne exposure or from wash water from high-pressure hoses, or from external equipment cleaning of the pump-shaft seal zone.”

Gramlich recommends considering sealless pumps in some food-and-beverage processing operations. “Sealless technology is taking the complexity and cost out of the traditional style of pumps,” he said. “The fear of the unknown as to when the system may go down due to pump failure is virtually eliminated. It can also reduce the need for stocking additional parts, and seals can be very difficult to clean.”

Preventive Maintenance Practices for Food & Beverage Pumps

When it comes to preventive maintenance, Gramlich recommends taking the first simple step of reading and understanding the operating manuals.

“Many plants have hundreds of pumps, and they are at different locations, and on different lines,” Gramlich said. “They are often forgotten pieces of equipment—until they fail. Then a production line goes down causing costly downtime. In addition to the manuals, it’s a good idea to have training videos on hand for the operators to use for training, but also during an emergency breakdown.”

Dillon and Gramlich agree that using the knowledge and expertise of channel partners is important. “The manufacturers’ distributors and service professionals know what they are doing and will come into your plant for maintenance training and product updates,” Gramlich stated. “This is part of what you pay for when you purchase the equipment, so use their expertise.”

It’s also a good idea to keep spare parts on hand in case of emergency breakdowns so the systems can be running again quickly, Gramlich said.

CIP Case Study 1: Sugar and Seals Positive Displacement Pumps

Gramlich described a scenario in which a customer was producing a sugar-based ingredient with various colors using positive displacement pumps with double mechanical seals and a water-flush system for the pumps.

“This is common since sugar is tacky and sticky,” Gramlich said. “Double mechanical seals can help prevent the seal faces from gluing together when the pump is shut down after a batch or run. Double-mechanical seals are expensive since you have two per pump shaft and two shafts per pump, and they require multiple parts. Plus you have the cost and complexity of the water-flush system that must be turned on prior to pump starting and turned off after operation.”

The cost of the flush water is of great concern in today’s environment where all companies are seeking to reduce carbon footprints and save resources, he added. “The water for the flush seals is not reused. It goes down the drain and increases the sewer cost fees for the plant, so they pay for it twice,” he said. “When this plant had a seal failure, the color from the pump in which the seal failed would leak on the floor and create a mess and waste of ingredients. At initial moment of failure, the color at the leak point would squirt out of the seals as the pump shaft rotated, spraying a 360-degree stream of that color throughout the room. This contaminated the other colors, and caused more loss of production, waste of ingredients, and increased sewer and maintenance costs.”

The solution was to install a Mouvex seal-less pump. This modification eliminated the need for seal parts and the use of water for the double-mechanical seal-flush systems. “The water saving alone was enough to provide the payback on the project,” Gramlich said. “Nobody, except the accounting department, thinks about the water bill, an often overlooked and wasted resource in facilities. Water waste is now being looked at, especially in areas such as California, that face water restrictions and higher rates.”

CIP Case Study 2: Yogurt and Sterilization

“Yogurt is processed in a reactor and afterward it is sent to a sterile aseptic filling machine,” Dillon said. “This machine packages the yogurt in a totally sterile environment. The package has been sterilized. The air is sterilized. It’s like a little clean room.”

The yogurt is sent to the top of a volumetric filler. Every packaging operation has one of these, Dillon stated. “It looks like a carousel, and it works like a carousel,” he said. The piston goes up and down, and the cylinder is filled with the product. As it rotates, the piston goes down and pushes the yogurt into the cup.

“There is a tank at the top of this filling machine that is filled with yogurt, soda, cottage cheese, or whatever other food product is being processed,” Dillon said. “This tank has a level control that puts out a 4-to-20-milliamp signal and goes to a pump. As the level goes down, the pump speeds up. As the level goes up the pump slows down to try to keep the level constant in this machine. There is a detector that is basically a rod. The higher the resistance on the rod, the more it lowers. That electric signal is fed to the pump control to tell it how fast to go.”

The customer can set this level at what is called the dead band, which limits how far up and down in the tank the pump will go. “This determines the speed of the pump, and what you really want is for the pump to slow down and speed up,” Dillon said.

“In this case, they set the level to be a very narrow range. The pump would go to a maximum speed very quickly and then shut off. This was tearing up everything. All the torque was causing a lot of bending and breaking. All kinds of terrible things can happen because of that high momentary load. You cannot run electric motors like that because they are rated for a certain amount of stops and starts. When this happens the production guys have set the levels, but the maintenance guys must live with the results.”

Dillon said the solution is simple—use variable-speed controls. “The VSDs will prevent the equipment from being subjected to high momentary loads and protect it from a severe reaction to the way the system was installed.”

Dillon offers simple advice when it comes to maintaining food-and-beverage process pumping systems. “In general, try to minimize the pressures,” Dillon said. “Pressure equals power, which equals wear on everything. Maximize pipe diameters and shorten the pipe runs. You pay for piping once, but you pay double for maintenance in the long run.”

This page contains affiliate links. If you click on the product links and make a purchase, it allows me to make a small commission at no extra cost to you! Thank you for your support and I hope you find value in this content!